Current Waveform Analyzer Repair

Diagnosis and Fault Resolution

Advanced Diagnostics:

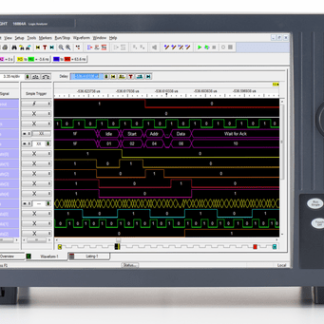

- Cutting-Edge Tools: Utilize state-of-the-art diagnostic equipment to accurately identify issues in Keysight current waveform analyzers, including signal processing errors, frequency inaccuracies, and component failures.

- Expert Analysis: Thoroughly analyze each identified issue to determine the root cause, enabling precise and effective repairs.

Precision Repairs

Adherence to Guidelines:

- NIST Compliance: Follow NIST guidelines during the repair process to ensure all repairs are traceable and meet stringent quality standards.

- Manufacturer Specifications: Adhere strictly to Keysight’s repair guidelines, using genuine or equivalent parts for replacements. This ensures the current waveform analyzers function as originally designed, maintaining their performance and reliability.

- Quality Components: Replace faulty components with high-quality parts to restore the original functionality and reliability of the analyzers.

- Skilled Technicians: Employ highly trained technicians with expertise in Keysight technologies, following detailed repair protocols to ensure the integrity and optimal performance of each device.

Comprehensive Rebuild Services

Component Replacement:

- Extensive Refurbishment: For analyzers requiring extensive refurbishment, replace worn or damaged parts such as input modules, circuit boards, and display units.

- Recalibration: After repairs, recalibrate the current waveform analyzers to ensure they deliver accurate and reliable measurements, aligning with the original manufacturer’s specifications.

ISO Calibration Services

Precision Calibration:

- Accurate Measurements: Provide ISO calibration services for Keysight current waveform analyzers to ensure precise measurement accuracy. Calibration procedures comply with ISO standards and are traceable to NIST, ensuring traceability, reliability, and adherence to international quality benchmarks.

- Standards Compliance: Follow strict guidelines set by NIST and Keysight to ensure the current waveform analyzers meet all technical and regulatory requirements.

Quality Assurance

Rigorous Quality Control:

- ISO Quality Management System: Implement a quality management system that complies with ISO standards, ensuring consistent quality and continuous improvement.

- Thorough Testing: Conduct rigorous quality control measures throughout the repair and refurbishment process to guarantee that every Keysight current waveform analyzer meets or exceeds manufacturer and NIST specifications.

- Performance Verification: Each device undergoes thorough testing to verify its performance, accuracy, and reliability before being returned to the customer.

Stocked Parts for Faster Service

Parts Availability:

- Extensive Inventory: Maintain a comprehensive inventory of parts specific to Keysight current waveform analyzers, significantly reducing repair times.

- Efficient Service: Complete most repairs and refurbishments without delays, minimizing downtime and enhancing customer satisfaction.

Showing all 2 results

-

Keysight CX3322A Waveform Analyzer Repair

$245.00 Request Repair -

Keysight CX3324A Waveform Analyzer Repair

$245.00 Request Repair

Showing all 2 results